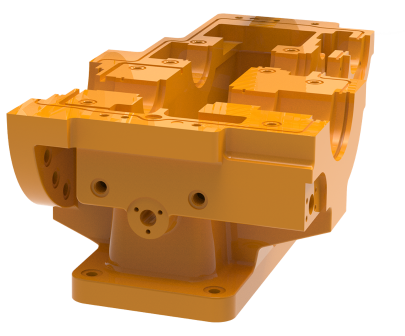

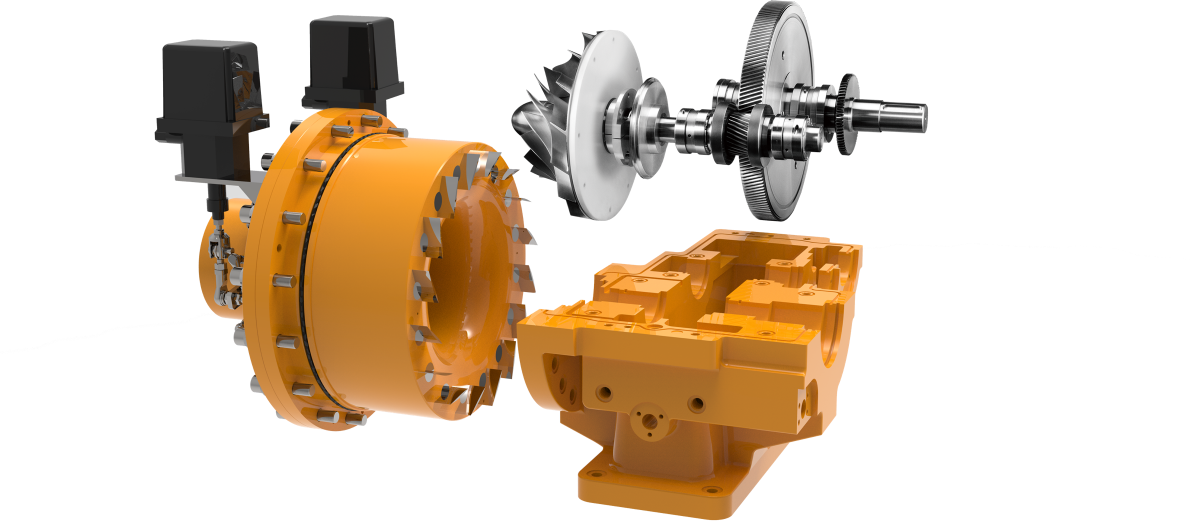

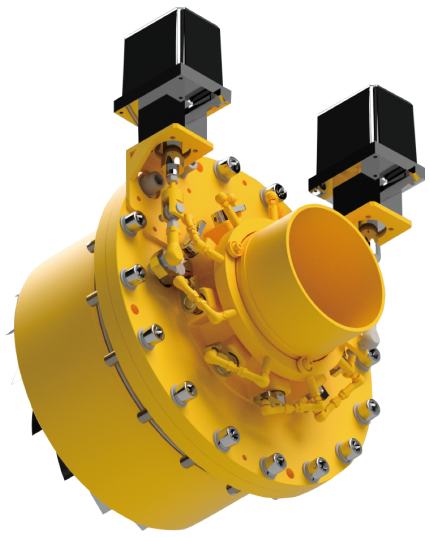

THE DRIVE SYSTEM

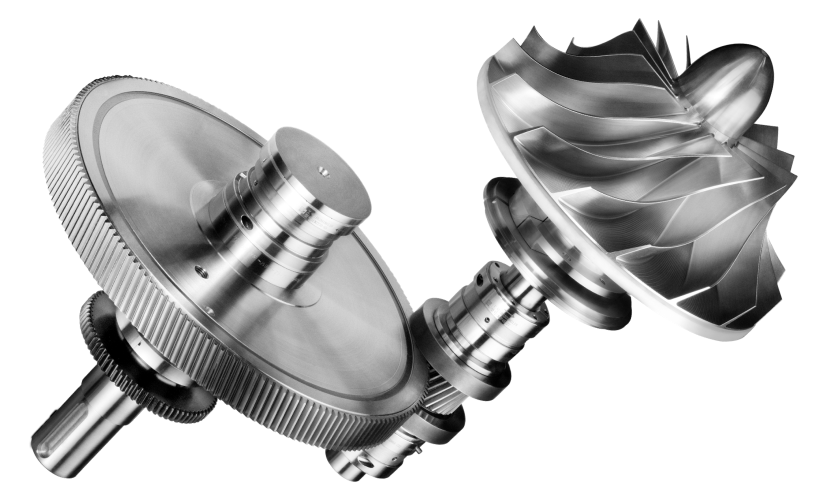

GEAR BOX

CAPACITY CONTROL

The rotor assembly is designed and engineered to meet or exceed

AGMA Q13 standard. The helical assembly offers smooth high-

speed operation. Precision and quality engineering ensures the

assembly is well balanced to minimize or eliminate vibration.

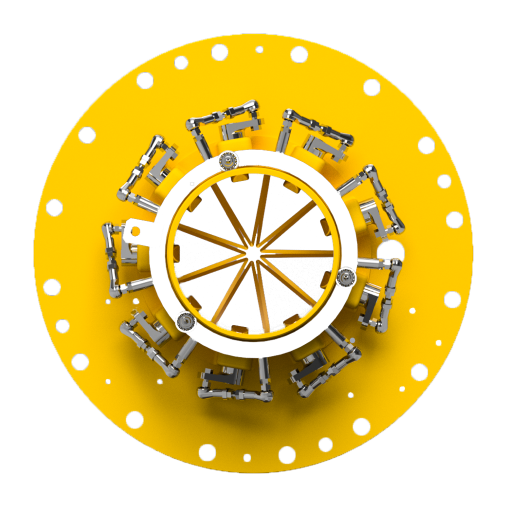

TILTING PAD BEARING

TAPERLAND THRUSTING

AND JOURNAL BEARING

INTEGRATED CENTRIFUGAL

BLOWER TECHNOLOGIES

innovation for efficiency

Bison turbo 's integrated centrifugal blower is designed with one thing in mind, to provide a highly efficient and optimum product.

Coupling the latest blower technology and Bison turbo 's innovative design team, the Bison turbo integrated centrifugal blower

exceeds previous models in terms of power optimization and energy efficiency, while at the same time reducing cost.

AERODYNAMIC ENGINEERING DESIGN

Lower Pneumatic Loss

EXCELLENT AERODYNAMIC PERFORMANCE

Efficiency Over 85%

DUAL AIR SEALING DESIGN

Theoretical Leakage less than 0.16Nm3/min

LUBRICANT FLOW

Lower Lubricant Flow-0.5l/s

Lower Power Consumption-1.7kW

HIRTH CONNECTION

Alignment Deviation Less Than 1μm

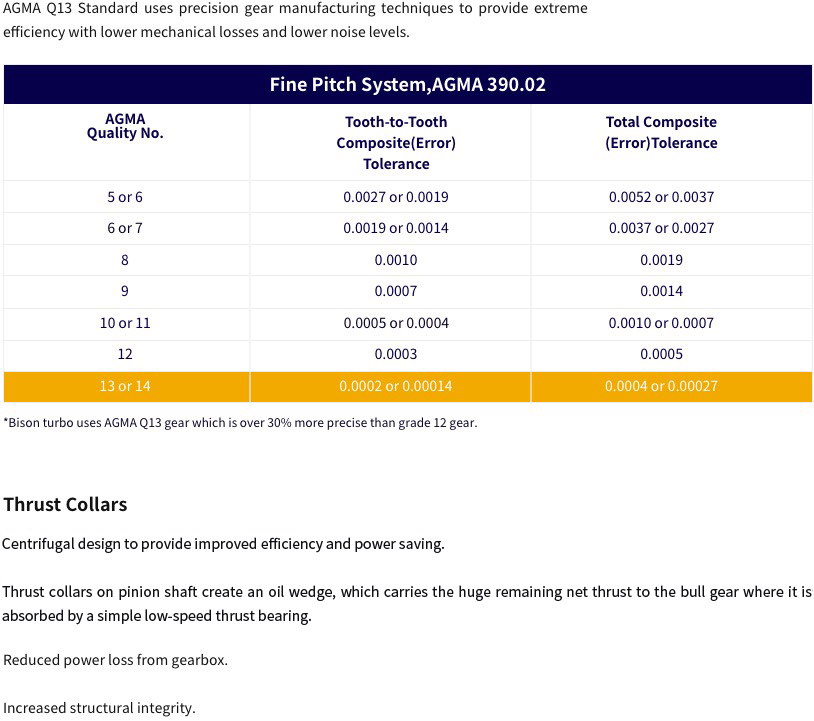

AGMA Q13 STANDARD

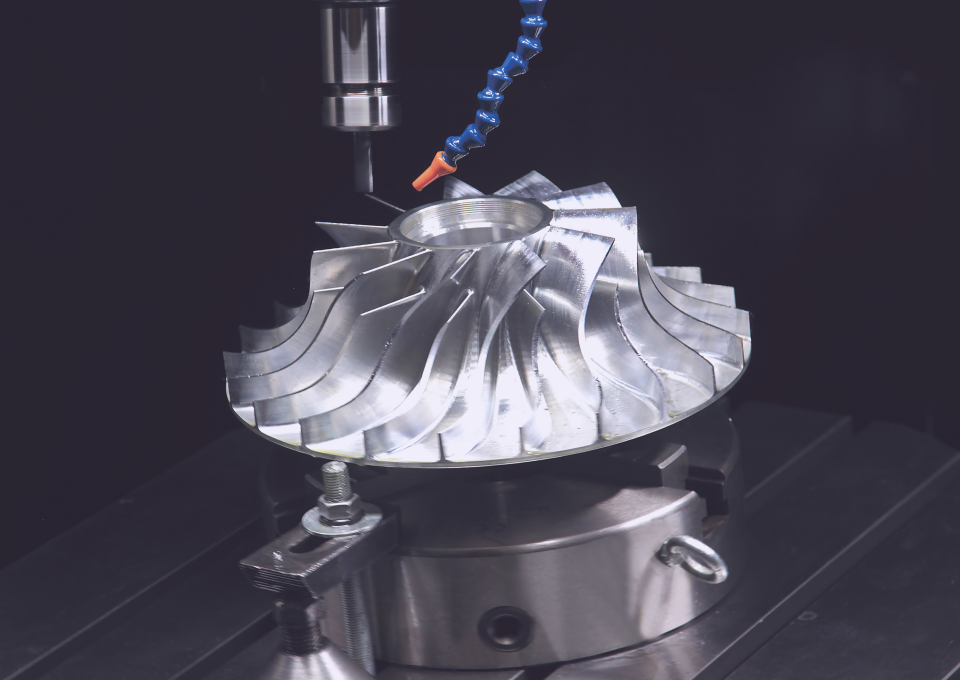

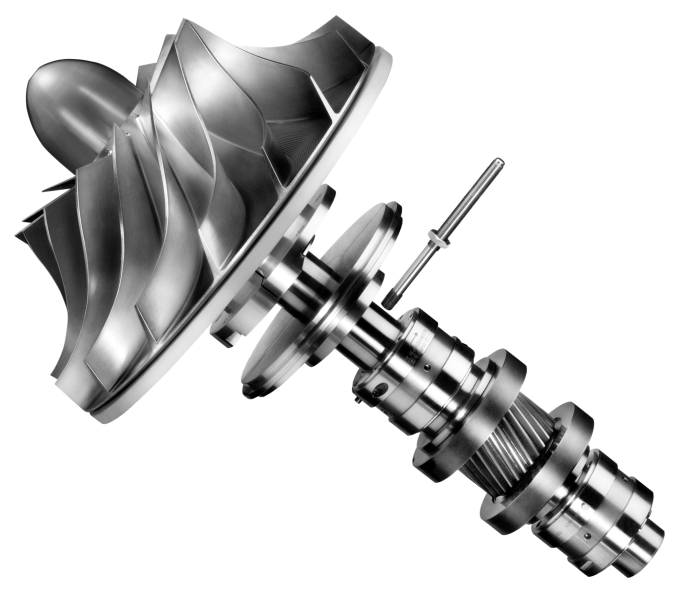

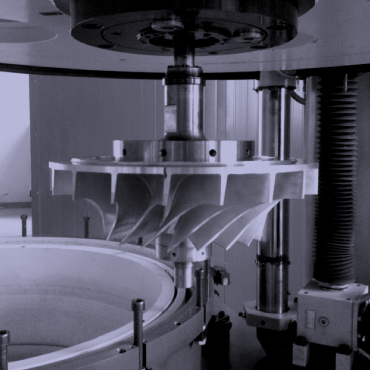

THE IMPELLER

Designed For High Efficiency And Reliability

-Proven reliability and enhanced efficiency

More backward Vane Design

Splitter blades Design (Higher Pressure)

- Designed specifically to meet aeration process requirements

- Tested to comply with all relevant standards

- Including but not limited to

120% overspeed test

Balance test: Grade 1 according to ISO1940

Ultrasonic Inspection

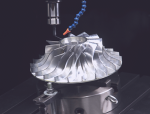

Precision Manufacturing for the best quality

Vertical turning centers

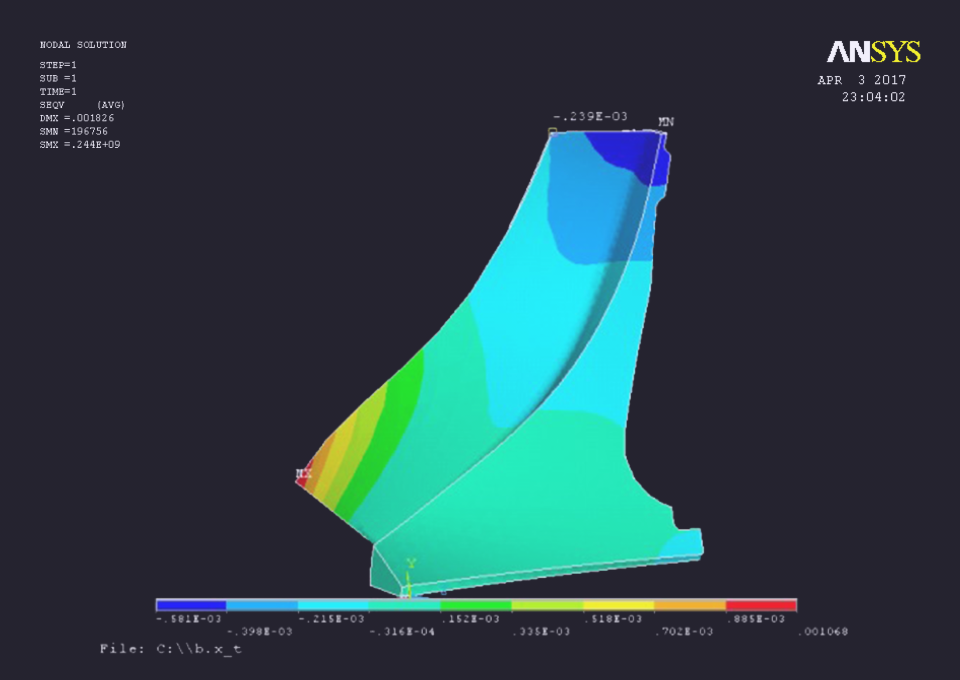

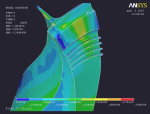

Designed in ANSYS for improved impeller aerodynamics

ASTM 7000 Series Aluminum Alloy Mechanical Properties

| Item | Ultimate tensile strength (UTS) KSI |

Tensile yield strength (TYS) KSI |

Elongation (EL4D) % |

Item | Plane Strain Fracture Toug-Hness (K1C) KSISQRIN |

| Longitudinal | 72 | 62 | 9 | L-T | 26 |

| Long Transverse | 72 | 62 | 6 | T-L | 23 |

| Short Transverse | 68 | 58 | 3 | S-L | 21 |

L-length/longitudinal;T-Width/long transverse;S-thickness/short transverse *Note: The data changes slightly with the batch of material.

Hirth Serration Connection

Precision engineered with attention to detail

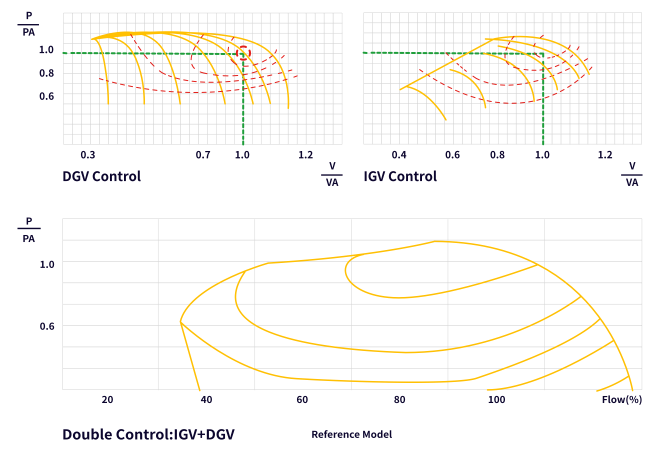

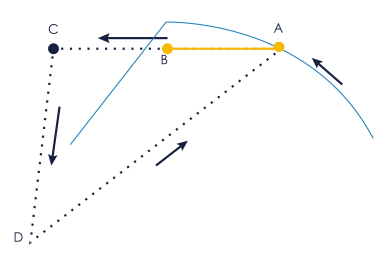

guide vane DGV

guide vane IGV

A variable inlet-guide vane IGV

CATERING FOR

DIFFERENT

CAPACITY NEEDS

Bison turbo Integrated Centrifugal Blower is designed to cater

for the different capacity needs of a waste water treatment

plant. The blower can be equipped with various capacity control

options to meet the demands of specific discharge pressure and

volume. Flexibility and efficiency is an integral part of the bison

turbo blower.

Capacity Control

THE CONTROL

SYSTEM

Comprehensive protection

and control

Vibration sensor installed between

tilting pad bearing and oil sealing

provides constant monitoring of the

pinion's operation condition to

protect the rotor assembly.

Temperature sensor monitors the change of

temperature in the tilting pad bearing to

ensure a safe operation.

Modulating

Blow-off Control

Blow-off silencer is used as a control mechanism to maintain constant pressure. This prevents frequent blower stop-start as excess gas is discharged

through the blow-off silencer when the pressure

reaches critical point.

INDEPENDENT LOCAL

CONTROL SYSTEM

Programmable logic control system provides optimal functionality and practicality for the Bison turbo blower.

PLC

Allen-Bradley CompactLogix platform

16 digital inputs |16 digital outputs|16 analog inputs|2 analog outputs

Performance control

Anti-surge control

Alarm history recall and record

PLC Panel

Supersized panel 1000*800mm

7" Colour touchscreen

Optional stainless steel enclosure available

USB port for data logging

Integrated auxiliary oil pump, oil mist fan and oil heater (optional) distribution system

BISON TURBO

CONTROL SYSTEM (BCS)

Designed to provide precise aeration.

| Bison Turbo Blower's BCS | Other Control System | |

| Control Method | Volume Control | Pressure Control |

| Process Energy Loss | No Loss | 5-10KPa |

| Remote Control and Analysis Interface | Standard | NA |

QUALITY CONTROL AND

WARRANTY

All bison turbo blowers are thoroughly and rigorously checked and tested before delivery. All tests are compliant with relevant standards such as PTC-10, API617/672. For quality assurance,bison turbo blowers can also undertake different simulated operating conditions that the customer may face.Bison turbo strives to deliver the best and most suitable product to the customers.

Bison turbo blowers come with an extended

5 year air- end warranty (optional)

BISON TURBO INTEGRATED

CENTRIFUGAL BLOWER

TECHNICAL DATA

- STB I

- Flow Range: 4,800 - 13,500 m³/hr@20° C

- Discharge Pressure Range: 0.3 - 2.2 barg

- Main Motor Power: 90 - 500 kW

- Main Motor Voltage: High/ Low Voltage

- Motor Starter: Star- Delta / Soft Starter

- Cooling Method: Air cooled / Water cooled